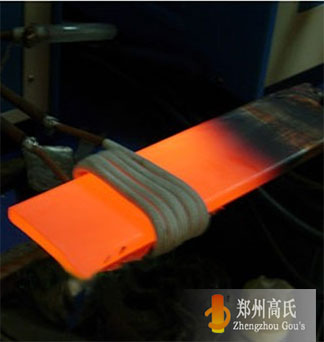

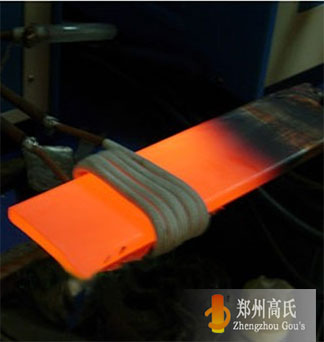

Last week, our old customer wanted a heating equipment for diathermy forging a rectangular steel plate with a thickness of 10mm and a weight of 2.5kg. It was required that the steel plate could be heated to about 1000°C within 15 minutes, and then the steel plate could be forged and formed. According to the customer's needs, the business staff recommended our medium frequency induction heating power supply to the customer through a series of calculations.

In steel and machinery manufacturing plants, when the workpiece to be heated has a large specification, whether it is for diathermy or quenching, the medium frequency induction heating power supply is more useful, because the machine frequency of the medium frequency is low, and the diathermy diameter is larger. It can quickly heat to the core of the workpiece, and the depth of quenching can also reach deeper. The medium frequency induction heating power supply produced by our company can realize the diathermy of workpieces with a diameter of 40-80mm, and the quenching of workpieces with a quenching hardness layer of 3-6mm. The processing capacity can fully meet the needs of customers. After customers understand our processing After the ability, even if you decide to sign a contract with us.

After last week's preparation, our customized medium frequency induction heating power supply was successfully shipped this week. In addition to the host and transformer, we also provide customers with 3 pairs of induction coils with different shapes according to the specifications of the workpieces to be heated by customers, as well as 1 copy of installation manual and 1 pair of foot switches.

en

en  cn

cn  jp

jp  ko

ko  de

de  es

es  it

it  ru

ru  pt

pt  vi

vi  th

th  pl

pl